As a homeowner, you've probably seen sunken or uneven concrete slabs around your property. Not only are they unsightly, but they can also be dangerous trip hazards. Moreover, this problem can affect many areas, including:

As a homeowner, you've probably seen sunken or uneven concrete slabs around your property. Not only are they unsightly, but they can also be dangerous trip hazards. Moreover, this problem can affect many areas, including:

- Garage floor slabs

- Basement floor slabs

- Patio slabs

- Walkway slabs

- Driveway slabs

- Pool deck slabs

- Porch slabs

Fortunately, you can solve this issue without the hassle and high cost of completely removing and replacing the slab. Raising concrete slabs with polyurethane is effective and cost-efficient.

Why Concrete Slabs Sink

Before explaining the solution, let's look at why slabs sink in the first place. Generally, a few common reasons include:

- Erosion from poor drainage or leaking pipes

- Poorly compacted soil during construction

- Decay of organic materials under the slab

Over time, these issues can create voids or destabilize the soil beneath your concrete, resulting in uneven settling.

The Benefits of Raising Concrete Slabs with Polyurethane

Polyurethane concrete leveling, also known as slab lifting or slab jacking, offers a highly effective way to raise and stabilize sunken concrete slabs. Specifically, the process involves drilling small holes into the slab and injecting expansive polyurethane foam underneath. As the foam expands, it fills voids, compacts the soil, and lifts the slab back into place.

Polyurethane foam to lift concrete has several advantages compared to mudjacking with cement grout or total slab replacement. Firstly, the process is minimally invasive, requiring smaller drill holes and less equipment. Secondly, the foam cures quickly, often allowing the slab to be used within 15 minutes after leveling. Additionally, its lightweight yet durable nature means it won't sink or wash away. Moreover, it's eco-friendly and NSF-certified to meet strict environmental standards. Lastly, it's more affordable than completely replacing the slab.

Is Polyurethane Concrete Leveling Right for Your Home?

In general, polyurethane slab lifting works well for most residential needs. However, total slab replacement might be necessary in some cases. For instance, if your slab is severely cracked or damaged across a large area, replacement may be a better long-term solution. Nevertheless, for most homeowners dealing with sunken garage floors, basement floors, patios, walkways, driveways, pool decks, or porch slabs, polyurethane lifting provides a quick, effective, and budget-friendly solution.

Next Steps for Homeowners

Uneven concrete slabs can compromise your home's safety and appearance. If you're thinking about fixing your settling slab issues, talk to a professional contractor who has experience with polyurethane foam lifting. They can assess your specific situation and help you determine the best solution for your property. Don't let sunken slabs diminish your home's value and aesthetics any longer. Take action today and enjoy the benefits of a level, safe, and attractive concrete surface.

Fill out this form or call 404-618-0438 for a contractor referral today!

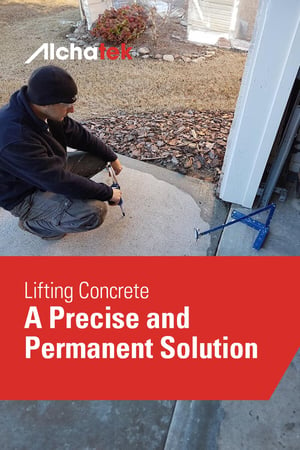

Do you have sinking or uneven concrete slabs around your home? Not only can they be an eyesore, but uneven walkways, driveways, and patios can also create tripping hazards and lead to costly accidents. Many homeowners assume their only option is to rip out the old concrete and pour new slabs. However, professional slab lifting offers a much better solution. Lifting concrete is a precise, permanent fix without the chaos and cost of ripping out and replacing old slabs. Keep reading to discover why slab lifting with polyurethane foam is the smart choice.

Do you have sinking or uneven concrete slabs around your home? Not only can they be an eyesore, but uneven walkways, driveways, and patios can also create tripping hazards and lead to costly accidents. Many homeowners assume their only option is to rip out the old concrete and pour new slabs. However, professional slab lifting offers a much better solution. Lifting concrete is a precise, permanent fix without the chaos and cost of ripping out and replacing old slabs. Keep reading to discover why slab lifting with polyurethane foam is the smart choice.

Sunken and uneven sidewalks are a common problem that can create trip hazards. Luckily, there's a fast and effective solution: sidewalk leveling using high-strength polyurethane foam. This innovative technique can raise sidewalks back to their proper height with minimal disruption and downtime compared to concrete replacement.

Sunken and uneven sidewalks are a common problem that can create trip hazards. Luckily, there's a fast and effective solution: sidewalk leveling using high-strength polyurethane foam. This innovative technique can raise sidewalks back to their proper height with minimal disruption and downtime compared to concrete replacement.

When fixing sunken or uneven concrete slabs, homeowners have a few options: repair with polyurethane, repair with mudjacking material, or replace the slab. Both polyurethane and mudjacking material lift and stabilize affected slabs without the need for complete demolition and replacement. However, notable differences exist between these approaches in price, effectiveness, and longevity. The cost of concrete leveling depends on these factors.

When fixing sunken or uneven concrete slabs, homeowners have a few options: repair with polyurethane, repair with mudjacking material, or replace the slab. Both polyurethane and mudjacking material lift and stabilize affected slabs without the need for complete demolition and replacement. However, notable differences exist between these approaches in price, effectiveness, and longevity. The cost of concrete leveling depends on these factors.

Essential Details

Essential Details

Sunken concrete slabs in your driveway can be a frustrating and unsightly problem. Not only do they detract from your home's curb appeal, but they can also create safety hazards for vehicles and pedestrians. Fortunately, there are effective ways to repair sunken slabs and restore your driveway to its original smooth, level surface. It’s essential to understand how to repair a sunken driveway properly.

Sunken concrete slabs in your driveway can be a frustrating and unsightly problem. Not only do they detract from your home's curb appeal, but they can also create safety hazards for vehicles and pedestrians. Fortunately, there are effective ways to repair sunken slabs and restore your driveway to its original smooth, level surface. It’s essential to understand how to repair a sunken driveway properly.

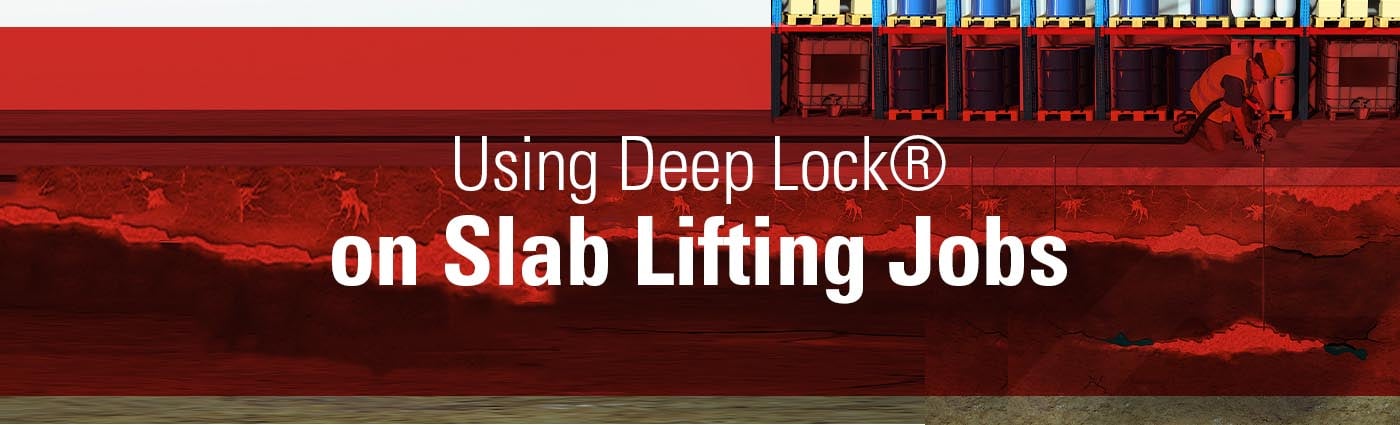

While Alchatek's Deep Lock® process is primarily used on deep soil stabilization jobs, there are specific situations in which deep soil stabilization may be needed to reinforce soil on slab lifting jobs. In cases where slabs are bearing heavy loads, have significantly loose soil underneath, or are located in areas where access is limited, incorporating the Deep Lock® process can help address the underlying soil stability issues. With the addition of the Deep Lock® soil stabilization process, contractors can achieve effective, minimally invasive slab lifting results while simultaneously improving the long-term stability of the foundation.

While Alchatek's Deep Lock® process is primarily used on deep soil stabilization jobs, there are specific situations in which deep soil stabilization may be needed to reinforce soil on slab lifting jobs. In cases where slabs are bearing heavy loads, have significantly loose soil underneath, or are located in areas where access is limited, incorporating the Deep Lock® process can help address the underlying soil stability issues. With the addition of the Deep Lock® soil stabilization process, contractors can achieve effective, minimally invasive slab lifting results while simultaneously improving the long-term stability of the foundation.

Essential Details

Essential Details

Alchatek, with its expertise in commercial property maintenance, stands ready to provide comprehensive support in addressing your concrete slab needs.

Alchatek, with its expertise in commercial property maintenance, stands ready to provide comprehensive support in addressing your concrete slab needs.

After identifying issues with concrete slabs in your commercial property, the next step is choosing the right repair method. The post-holiday slowdown offers the perfect timing for such repairs, and understanding the available solutions is key to making an informed decision.

After identifying issues with concrete slabs in your commercial property, the next step is choosing the right repair method. The post-holiday slowdown offers the perfect timing for such repairs, and understanding the available solutions is key to making an informed decision.