This article is an excerpt from Episode 7 of Alchemy-Spetec's podcast The Injection Connection, featuring concrete lifting marketing expert Ann Thaxton of ConcreteTitans.com. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this exchange is posted at the bottom of the article.)

This article is an excerpt from Episode 7 of Alchemy-Spetec's podcast The Injection Connection, featuring concrete lifting marketing expert Ann Thaxton of ConcreteTitans.com. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this exchange is posted at the bottom of the article.)

Jim Spiegel: As you know in the industry it's very expensive to get into this, just on the equipment side of things. You're looking at 50, 60, 70, even more - $100,000 perhaps depending on your rig setup. So, one of the questions we get all the time is – “Okay, I'm going to invest in this equipment. What are you going to do for me and how do I get leads?” That's probably the number one question. For the customers that buy the equipment, their biggest problem we see as far as their success is their lack of marketing or advertising strategy. Say I'm Joe the builder and I want to get into this, and my first question is, “How do I start? Where do I even start with marketing, advertising and lead capture?” Could you talk us through what solutions you may offer on that and any information on monthly budgets?

Ann Thaxton: We've found throughout the industry that for cost per lead, your cheapest cost per lead is digital advertising. Your most expensive cost per lead is TV. And everything else falls in between. Your average cost per lead with digital advertising runs between $40 and $50 per lead. TV runs around $200 to $250 per lead. Direct Mail runs about $150 per lead. Ideally, if you were a more mature company, you would do all of those because studies show that it takes anywhere between 12 and 18 touch points for somebody to convert to become a customer. If you're just starting out in the business, your cheapest cost per lead is digital advertising. But I wouldn't just stop there. If you have time on your hands and if you are able to, then print up some door hangers and hang them up around neighborhoods where you know they have some problems with their concrete. If you level concrete in one neighborhood, you hang door hangers on both sides of that house and across the street for sure. And you ask your customer if they would please refer people to you because referrals are really the gold standard here. Referrals are “free” cost per lead. So, once you get really mature as a company, you get so many referrals that it just becomes gravy on top. But to start out, I would think that you would do a lot of that pounding the pavement type of work to get your name out and then do some lead advertising. And I have different levels of service. From the start, from the starting service up to 4+ rig companies. And for a budget to start out, you can spend less than a thousand a month.

Visit ConcreteTitans.com for more info on Ann Thaxton's marketing services.

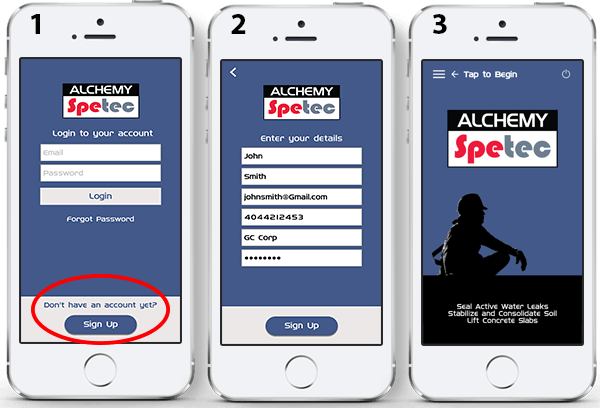

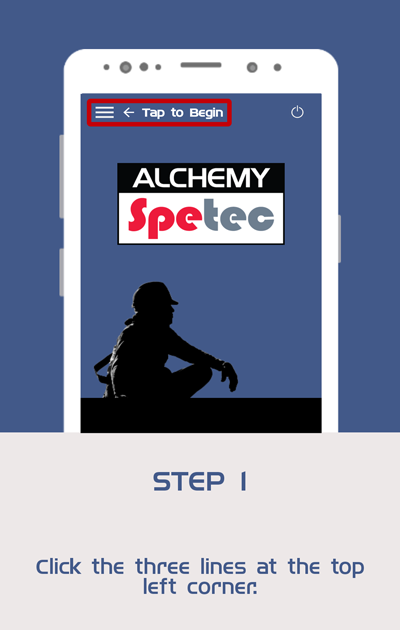

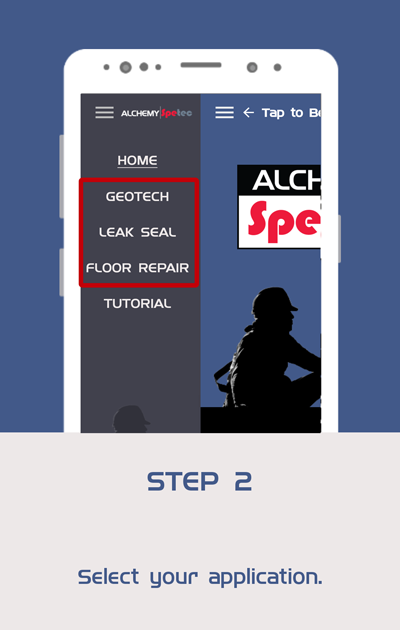

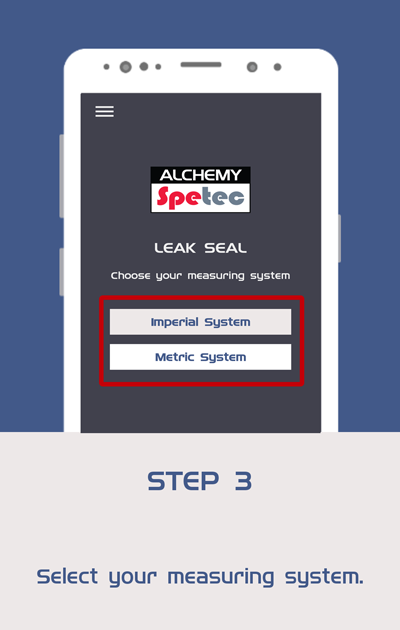

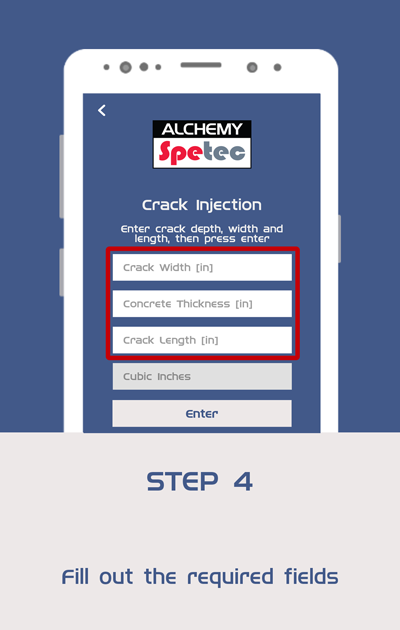

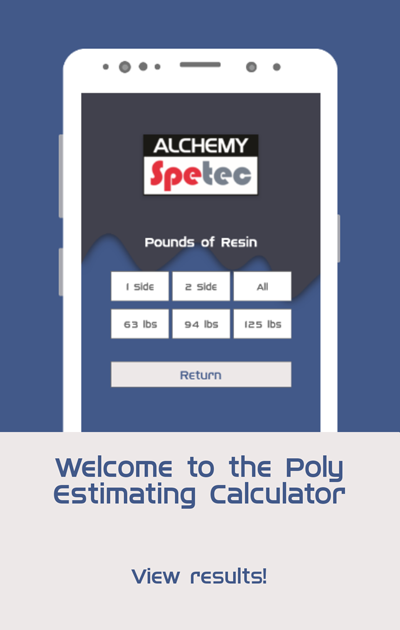

Did you know that Alchemy-Spetec offers a customized version of the popular

Did you know that Alchemy-Spetec offers a customized version of the popular

We often get calls from spray foam insulation installers who are interested in adding slab lifting capability to their rig set up. If you're reading this article, you yourself may be looking for info on the matter. If so, we have good news for you. With just four additional pieces of equipment and one set of material, you can quickly and easily add slab lifting to your service offerings. Let’s take a look at exactly what additional equipment and material you'll need to get started...

We often get calls from spray foam insulation installers who are interested in adding slab lifting capability to their rig set up. If you're reading this article, you yourself may be looking for info on the matter. If so, we have good news for you. With just four additional pieces of equipment and one set of material, you can quickly and easily add slab lifting to your service offerings. Let’s take a look at exactly what additional equipment and material you'll need to get started...

On Episode 7 of The Injection Connection, host Jim Spiegel sits down with Ann Thaxton, from

On Episode 7 of The Injection Connection, host Jim Spiegel sits down with Ann Thaxton, from

Jim and guest Jack Whitworth, 26-year chemical grouting sales professional, discuss the importance of education, mutual benefits of competitors working together, and driving our families crazy during the Covid-19 lockdown time. (Jim Spiegel is Vice President of

Jim and guest Jack Whitworth, 26-year chemical grouting sales professional, discuss the importance of education, mutual benefits of competitors working together, and driving our families crazy during the Covid-19 lockdown time. (Jim Spiegel is Vice President of

Polyurethane – Quality and Selection

Polyurethane – Quality and Selection