Deep Lock® is a specialized deep soil stabilization process developed by Alchatek. It involves injecting a structural polymer deep into the soil, where it expands and solidifies. This process enhances the stability and strength of the soil, making it an effective solution for various geotechnical challenges. One key feature of Deep Lock® is its ability to stabilize soil below the freeze/thaw line, making it particularly useful in cold weather conditions.

Deep Lock® is a specialized deep soil stabilization process developed by Alchatek. It involves injecting a structural polymer deep into the soil, where it expands and solidifies. This process enhances the stability and strength of the soil, making it an effective solution for various geotechnical challenges. One key feature of Deep Lock® is its ability to stabilize soil below the freeze/thaw line, making it particularly useful in cold weather conditions.

Applications of Deep Lock® in Cold Weather

- Foundations: Deep Lock® is extensively used to stabilize and strengthen foundations, especially in areas where the soil is compromised due to moisture or other factors.

- Under Sunken Slabs: For sunken slabs, where soil erosion or voids have occurred deeper down, Deep Lock® provides an effective solution to fill and stabilize these gaps.

- Settling Structures: Entire structures that are settling, not just the slab, can benefit from the deep soil stabilization offered by Deep Lock®.

- Interior Footings: In scenarios where exterior piers are used for stabilization, Deep Lock® can be employed for interior footings, avoiding damage to floors and providing a balanced stabilization approach.

- Brick and Stone Foundations: These types of foundations, which are challenging to stabilize with piers, can be effectively supported using the Deep Lock® process.

- Pre-construction Soil Stabilization: Before construction begins, stabilizing the soil ensures that the foundation rests on solid ground, a crucial step for long-term structural integrity.

- Culverts: Deep Lock® can be used for stabilizing and sealing culverts both from the outside (probe-grouting style) and from the inside by injecting the polymer just below the steel.

Why Deep Lock® is Used in Cold Weather

Cold Weather Performance: Deep Lock® can be performed even when the top layer of soil is frozen, making it ideal for cold weather applications.

- Addressing the Root Cause: By stabilizing soil deep below the surface, Deep Lock® addresses the underlying causes of structural problems rather than just the symptoms.

- Preventing Resettlement: It ensures that once slabs or structures are stabilized, they remain in place without resettling.

- Warranty Benefits: When employing the Deep Lock® process, contractors can offer better warranties due to effective and long-lasting stabilization.

- Ease of Process: The process is relatively easy to learn and implement, making it a practical option for a wide variety of contractors.

Deep Lock® offers a versatile and effective solution for a range of soil stabilization needs, particularly beneficial in cold weather conditions. Its ability to work below the freeze/thaw line and address deep-rooted soil issues makes it an invaluable tool in the geotechnical contractor’s arsenal.

Polyurethane grouting is an essential process in construction and infrastructure projects with the need to lift structures, fill voids, and stabilize soil. While polyurethane grouting has been utilized for decades, advancements in technology and technique have enabled a new level of precision and control in modern grouting applications. Innovations in polyurethane injection methods and equipment allow design and construction teams to achieve highly accurate, consistent injections for maximum strength and longevity.

Polyurethane grouting is an essential process in construction and infrastructure projects with the need to lift structures, fill voids, and stabilize soil. While polyurethane grouting has been utilized for decades, advancements in technology and technique have enabled a new level of precision and control in modern grouting applications. Innovations in polyurethane injection methods and equipment allow design and construction teams to achieve highly accurate, consistent injections for maximum strength and longevity.

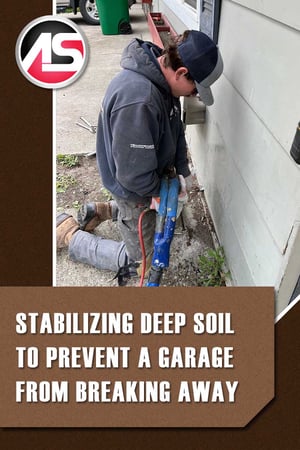

The owner of a home in Montana contacted

The owner of a home in Montana contacted

A property owner in Montana contacted geotech contractor

A property owner in Montana contacted geotech contractor