.png?width=899&height=273&name=mechanical%20packer-banner%20(2).png)

.png?width=320&name=mechanical%20packer-blog%20(1).png) The term ‘Mechanical Packer’ probably doesn’t mean much to those not in the concrete repair industry. But for those close to chemical grouting, this term certainly brings about thoughts of both form and function. Mechanical packers are also referred to as ports, or more simply, packers. But we would like to be very clear that a port is not a packer.

The term ‘Mechanical Packer’ probably doesn’t mean much to those not in the concrete repair industry. But for those close to chemical grouting, this term certainly brings about thoughts of both form and function. Mechanical packers are also referred to as ports, or more simply, packers. But we would like to be very clear that a port is not a packer.

Mechanical packers were designed to withstand high pressure injection applications by inserting them into pre-drilled holes in a concrete substrate at various diameters ranging most commonly from 1/4" – 5/8”. Mechanical packers feature a rubber base with a threaded shaft. As the threaded shaft is tightened, the rubber base is compressed, creating a compression seal inside the drill hole. The ultimate pressure tolerance is dependent upon the amount the rubber is expanded and the total surface area of the rubber base that is in contact with the drill hole. That is, a smaller diameter packer will have considerably less surface area of rubber compressed against the concrete side walls, and thus holding a lower amount of pressure when connected to high pressure equipment. Most job site and substrate conditions will permit successful injection results with a diameter of 3/8” – 1/2". Of course, some contractors have personal preference of smaller or larger sizes.

Concrete packers also come in various types. Suppliers will market benefits of steel, brass, zinc, or aluminum. All things considered, steel packers tend to be the most versatile packers as they are compatible with all chemical grout types, while the brass, aluminum, and zinc can exhibit signs of deterioration when using oxidizing agents such as the salt component in a polyacryate gel. However, some contractors insist that the breakdown is not as quick as marketed by suppliers, therefore utilizing brass and aluminum packers in these applications as well.

Each packer features an anti-return ball valve that is opened under pressure, allowing the passage of chemical grouts. Upon depressurizing, the ball valve will close, prohibiting the return flow of the injection resin out of the drill hole. This ball valve can be located on the top of the packer, in the base of the packer, or even freely-floating in the packer shaft to allow for maximum flow. There are pros and cons to each ball valve location depending on job site condition and application and finishing techniques.

Lastly, there are plastic alternatives commonly referred to as ‘bang-in’ or ‘hammer-in’. These packers do not have the threaded metal shaft, but as they are driven into the drill hole, the same compression seal theory takes hold as the tapered edges become lodged into the drill hole sides. Another form of plastic ports is a plastic, surface-mounted version that is commonly used in epoxy injection and/or in the event that drilling into the substrate would be considered harmful or ill-advised.

For more detail on your specific project needs and packer or port recommendation, please contact a knowledgeable Alchemy-Spetec representative at 404-618-0438. Alchemy-Spetec offers all of the packers and ports listed above, as well as all of the chemical grouts and pumping systems required to make your next chemical grouting job a success!

Want more information on Alchemy-Spetec mechanical packers?

You meet someone for the first time, have a productive and promising conversation, exchange business cards, rinse, and repeat. As I’m sure the case is with many of you reading this, I’ve had this exchange with hundreds of people during this tradeshow season, and sincerely wonder if the connections that were made in the exhibit hall were carried through optimally.

You meet someone for the first time, have a productive and promising conversation, exchange business cards, rinse, and repeat. As I’m sure the case is with many of you reading this, I’ve had this exchange with hundreds of people during this tradeshow season, and sincerely wonder if the connections that were made in the exhibit hall were carried through optimally.

The

The

Hydroactive chemical grouts, by definition, require hydrogen molecules from water to initiate the polymerization reaction. Typically, an ISO component is catalyzed by an amine, but this solution will remain unreacted until it comes in contact with hydrogen. All of the contractors out there familiar with chemical grouts are familiar with the ‘skin’ on the top of a catalyzed batch. This is simply the top layer of the catalyzed batch showing signs of initiation just through contact with moisture in the air. For injection into active leaks, these products are a slam dunk. But what happens when you get to the job, and there is no leak where there was one just a few days ago?

Hydroactive chemical grouts, by definition, require hydrogen molecules from water to initiate the polymerization reaction. Typically, an ISO component is catalyzed by an amine, but this solution will remain unreacted until it comes in contact with hydrogen. All of the contractors out there familiar with chemical grouts are familiar with the ‘skin’ on the top of a catalyzed batch. This is simply the top layer of the catalyzed batch showing signs of initiation just through contact with moisture in the air. For injection into active leaks, these products are a slam dunk. But what happens when you get to the job, and there is no leak where there was one just a few days ago?

Waterproofing is a broad term in the construction world. The distinctions of above-grade and below-grade pretty well sum up the offerings out there. But when considering chemical grout’s place in the waterproofing world, we primarily stick to below-grade applications.

Waterproofing is a broad term in the construction world. The distinctions of above-grade and below-grade pretty well sum up the offerings out there. But when considering chemical grout’s place in the waterproofing world, we primarily stick to below-grade applications. .png?width=1024&name=conference%20room%201-banner%20(10).png)

Perhaps even more eloquent than e=mc2 is Isaac Newton’s Second Law of motion, F=ma. For all of those fellow physics enthusiasts out there, we all know how F=ma is the flathead screwdriver in the formula toolbox; and for good reason. The amount of Force generated by any individual object being equal to the object’s mass multiplied by the acceleration of that object has profound proofs across the universe that can also be observed in our everyday partnerships.

Perhaps even more eloquent than e=mc2 is Isaac Newton’s Second Law of motion, F=ma. For all of those fellow physics enthusiasts out there, we all know how F=ma is the flathead screwdriver in the formula toolbox; and for good reason. The amount of Force generated by any individual object being equal to the object’s mass multiplied by the acceleration of that object has profound proofs across the universe that can also be observed in our everyday partnerships..png?width=1024&name=conference%20room%201-banner%20(9).png)

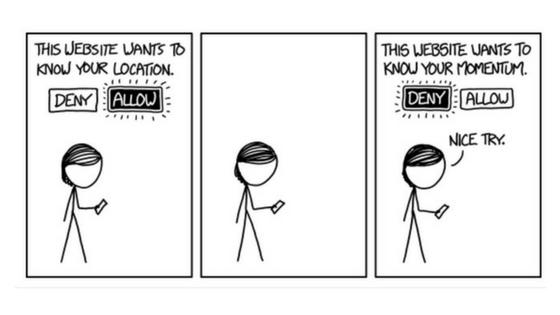

In 1927, a German physicist, Werner Heisenberg, introduced what would become the Heisenberg Uncertainty Principle. In short, his theory maintained that two very distinctive properties when examining any particle, location and momentum, could not be accurately measured at the same time. The more one knows about one value, the less it knows about the other. So how does this relate to business?

In 1927, a German physicist, Werner Heisenberg, introduced what would become the Heisenberg Uncertainty Principle. In short, his theory maintained that two very distinctive properties when examining any particle, location and momentum, could not be accurately measured at the same time. The more one knows about one value, the less it knows about the other. So how does this relate to business? .png?width=560&height=315&name=Untitled%20design%20(1).png) The physical world around us is made up of particles. You, me, the buildings we work in, and the computer screen you’re looking at; all made up of particles. So, let’s be careful on the amount of granularity that we all aim to achieve in decision making processes. The often-quoted phenomenon of analysis paralysis lies in the Uncertainty Principle. The more you examine one aspect of any given part of the physical world, products and opportunities included, the less you know about another aspect. There’s no way around this.

The physical world around us is made up of particles. You, me, the buildings we work in, and the computer screen you’re looking at; all made up of particles. So, let’s be careful on the amount of granularity that we all aim to achieve in decision making processes. The often-quoted phenomenon of analysis paralysis lies in the Uncertainty Principle. The more you examine one aspect of any given part of the physical world, products and opportunities included, the less you know about another aspect. There’s no way around this.-1.png?width=1024&name=mechanical%20packer-banner%20(4)-1.png)

.png?width=320&name=mechanical%20packer-blog%20(3).png) Continuing on from the previous overview of

Continuing on from the previous overview of

.png?width=899&height=273&name=mechanical%20packer-banner%20(2).png)

.png?width=320&name=mechanical%20packer-blog%20(1).png) The term ‘Mechanical Packer’ probably doesn’t mean much to those not in the concrete repair industry. But for those close to chemical grouting, this term certainly brings about thoughts of both form and function. Mechanical packers are also referred to as ports, or more simply, packers. But we would like to be very clear that a port is not a packer.

The term ‘Mechanical Packer’ probably doesn’t mean much to those not in the concrete repair industry. But for those close to chemical grouting, this term certainly brings about thoughts of both form and function. Mechanical packers are also referred to as ports, or more simply, packers. But we would like to be very clear that a port is not a packer.